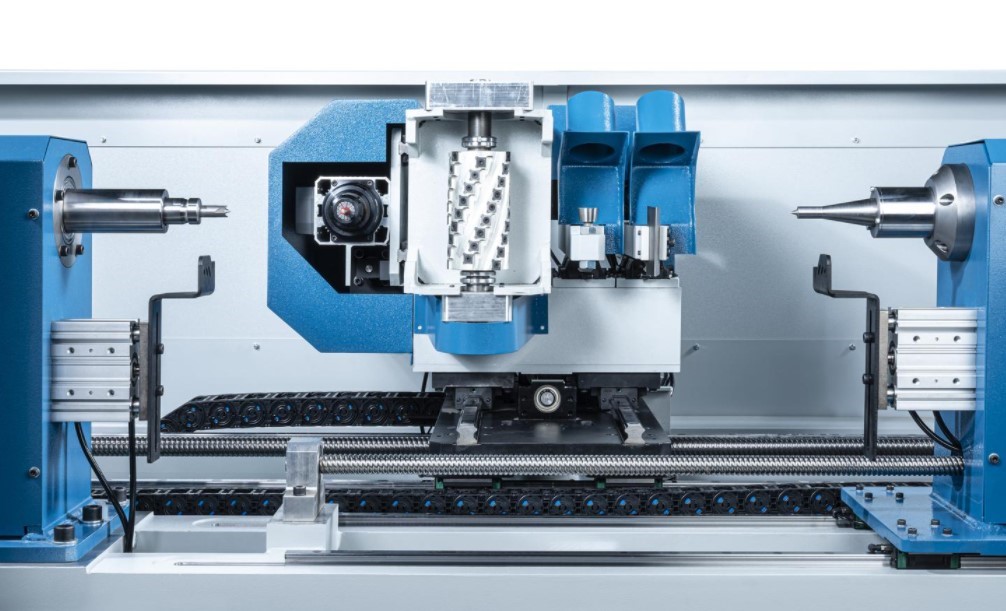

Pantograph machines work similarly to conventional devices. This product, which is frequently preferred during the processing of rotating parts, has technical features. This product, which cannot be produced easily thanks to its complex design, can be operated quite simply. Pantograph machines used for turning are also known as CNC machines. The working principle of the product depends on the lathe. There are many different parts connected to the lathe machine. Turning occurs due to the large number of axes. The driven cutout model is very useful. Parts that can be fixed by turning can also be fixed without rotation for some functions. Cutting wood saves time in operations with a driven cutter.

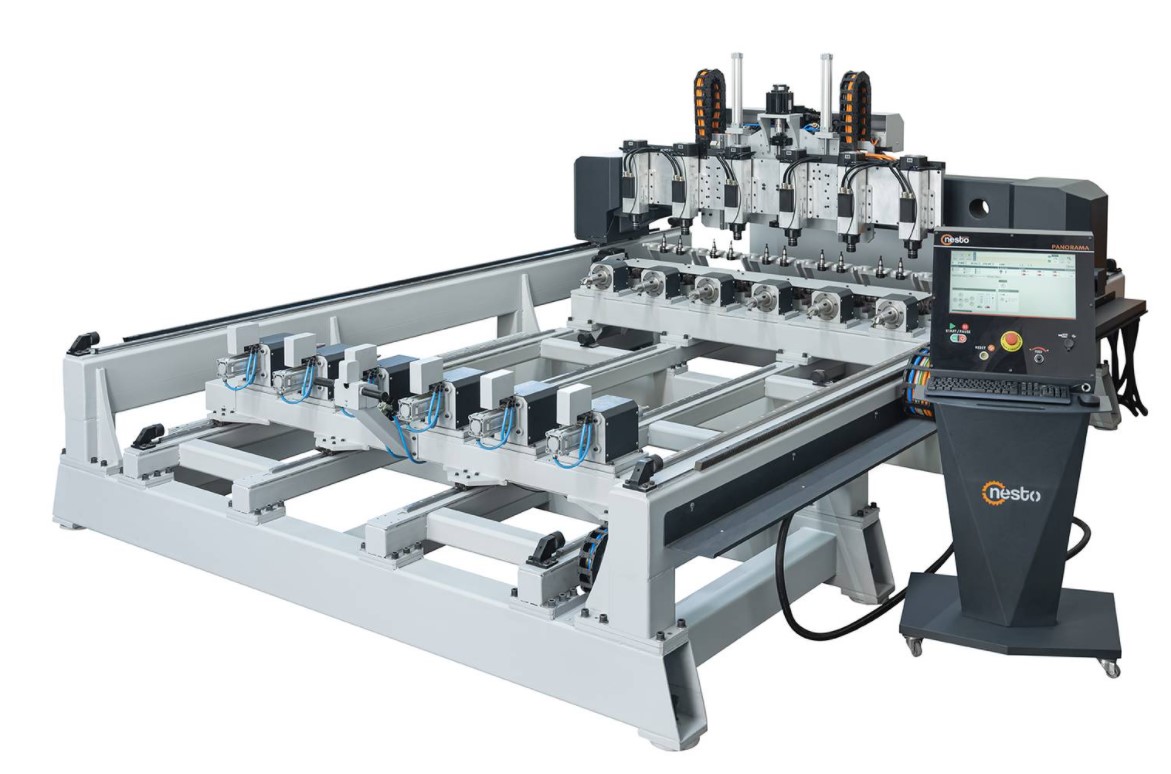

Axis Pantograph Machine

Thanks to the Axis Pantograph Machine, tenon holes can be drilled on wood or different raw materials. Those who want can easily access the parts of this device. The standard dimensions of the tenon end will ensure better quality processing of raw materials. Generally, standard procedures are used when opening the tenon. Standard procedures ensure that products reach users quickly. Ease of use in pantograph machines is due to the simplicity of the screen interface. People who want to get the product outputs in their company in the fastest way can get their requests in the fastest way. Measures and evaluations are set automatically in the device.

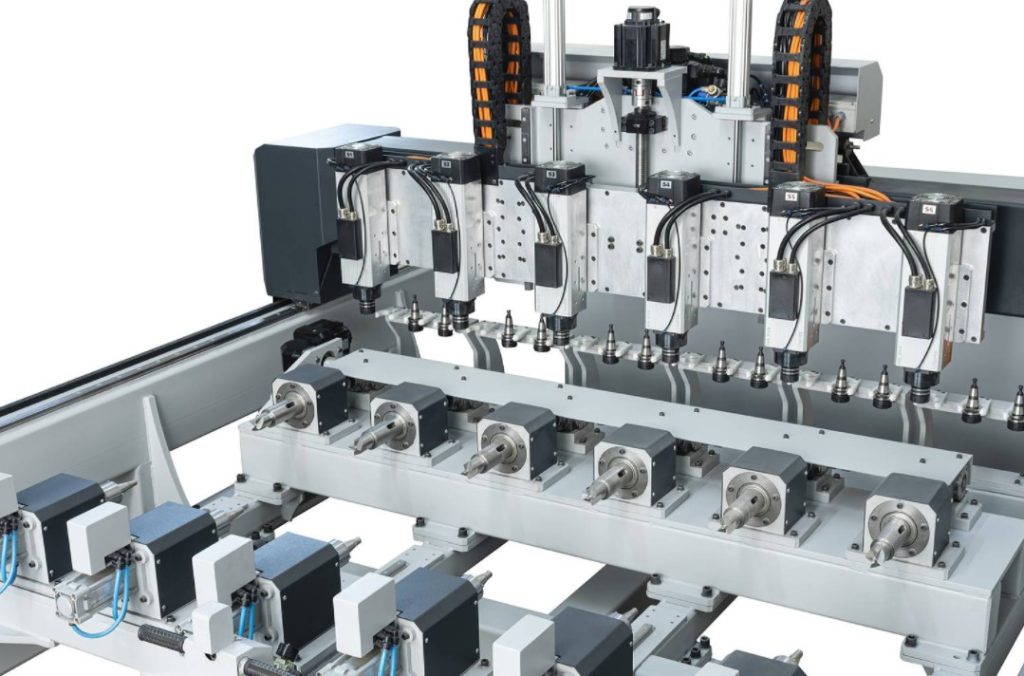

Pantograph Machine Technical Structure

The technical structure of the pantograph machine works with rudman sprin. This structure has a ceramic design. The device works with 6 units of 5 kW power. The product, which has a design of 24 thousand RPM, is specific to business engines. Firms working in workplaces with the operating engine will be satisfied with the pantograph machine. The operating motors of the device have 3 tool changing mechanisms. There are chassis reinforcement products on the device. This model, which prevents vibration and causes a faster device opening, can also be used as a rigid chassis. Lubricating products work automatically on the product and do not get help from human hands. In this way, results are achieved much faster.

Pantograph Machine Working Mechanism

Pantograph machine is not a specialized product for different sectors. The product that can be used in every sector has fixed features. There are different axes on the machine, similar to other cutting machines. The number of axes varies between two and five. A two-axis pantograph device has less than a five-axis function. If you are looking for a comprehensive product in your workplace, you can choose the four-axis pantograph machine. This model, which will serve the knees for many years in your workplace, includes processes such as cutting, marking and coat.

2-Axis Pantograph Device

The biaxial device has two different working areas. Servo motors are used on the two-axis model as in the five models. Servo motors operate in certain periods. You can find the high performance you are looking for in your workplaces thanks to this product. You can get help from this device to cut wood in the fastest way.

4-Axis Pantograph Device

Thanks to the four-axis pantograph device, you can obtain woods with different motifs. The axes in the device work with different servo motors. There is a mechanism working with high speed inside the machines. A sensitive acceleration is used in the servo motor of the machine. You can use this device for sharp results. Movements between the axes cause vibrations. The device has a simple instruction manual to make your wood cutting process easier. The device, which is produced with quality materials, can be used in many products from rails to cars. Therefore, you can use the machines in different sectors.