Nesto Machine

Nesto CNC combines advanced technology and high quality in machine production. Nesto aims to offer first-class quality CNC wood lathe machines to its customers. Thanks to the professional team, customers have the best results in line with their goals and wishes. The service offered by Nesto Machinery Industry Company continues after the CNC machine sale and customers can benefit from the after sales service whenever they wish.

Nesto High Quality CNC Wood Lathe Machines

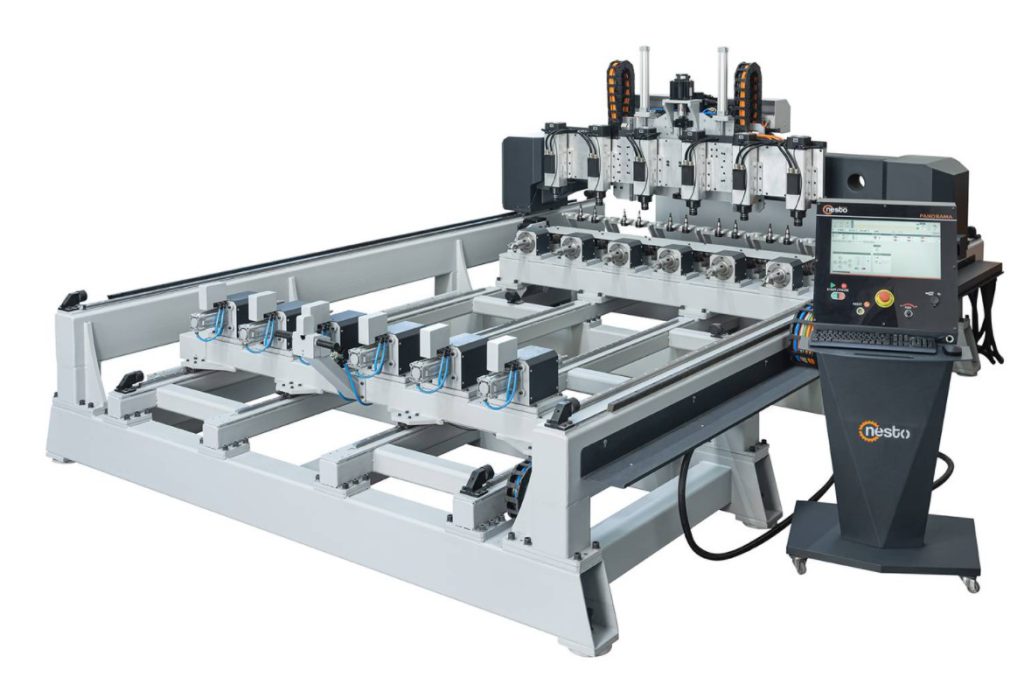

Nesto’s professionalism is focused on CNC wood lathe machines. Machine options sold include:

- 5 Axis CNC Wood Lathe Machine

- 4 Axis CNC Wood Lathe Machine

- 3 Axis CNC Wood Lathe Machine

- 2 Axis CNC Wood Lathe Machine

Changing the number of axes makes the use of CNC wood machines effective in different sized areas. 2 axis CNC wood lathe machines are ideal for detailed work in smaller spaces. Companies generally prefer 2 or 3 axis wood CNC machines for both ease of use and getting used to larger scale machines. They are also ideal for small businesses.

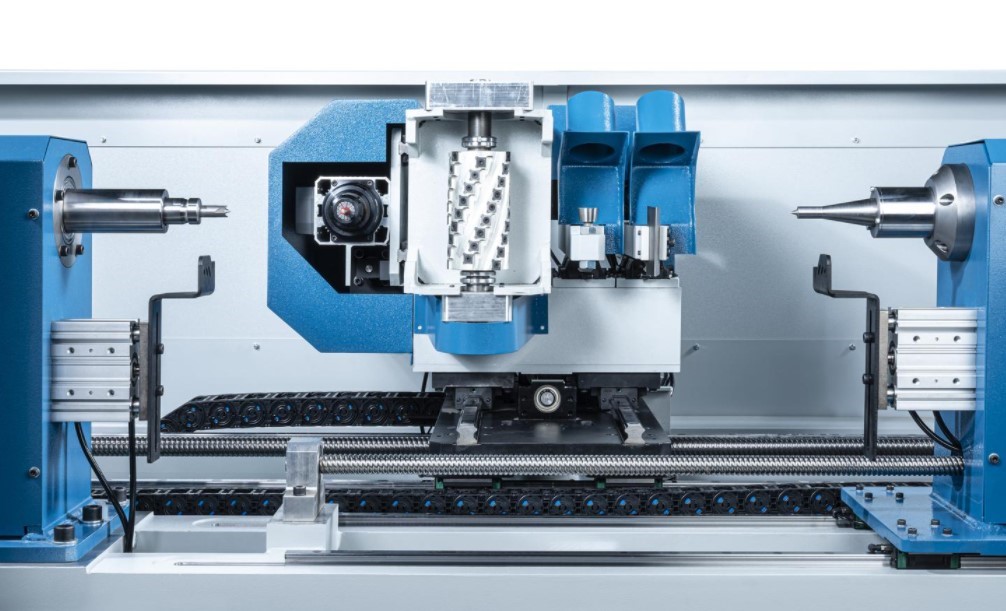

On the other hand, the 4 Axis CNC wood lathe machine options have rotary table divisor software, making them especially ideal for processing motifs or text on round pieces. Products can be processed without stretching.

With 5 axis CNC wood lathe machines, much more complex results can be obtained compared to other machines. The cutting edge easily reaches the entire surface. It is thought to have complex programming at the first stage, but it can be easily used with CAM & CAD software. The precision machining mechanism allows the user to achieve the desired results.

What to Consider When Choosing CNC Machines?

If you ask yourself to ‘’How do I choose the best CNC machine for woodworking?’’ then you have come to the exact right place, as our guide aims to help you choose the perfect machine.

1. Purpose of usage

The purpose of use is the first and most important criterion. The answers to questions such as what type of parts are desired to be processed while using the machine, how much the dimensions and weights are, and how detailed the work will be are important. Nesto’s professional team assists customers in this process, from specifying insert and tool specifications to deciding on the right hardware.

2. Controller preference

Control unit choice is another important issue. Which part will be produced should be taken into consideration and preference should be made depending on the processing style. In particular, it is very important to ensure that the production takes place quickly without loss of time. Efficiency and comfort should also be considered.

3. Ease of Use

It is extremely difficult to operate a machine that is messy and has buttons all over it. For this reason, a CNC machine should be easy to use, even if it works in a complex and detailed way. In addition to all these, the security system must work effectively and be able to completely stop the system when necessary.